- Best Phone:

0755-29750001

2020-05-12

Since the creation of MIM technology, with the different binder systems, a variety of MIM process paths have been formed, and degreasing methods are also diverse. The degreasing time has been shortened from the first few days to the current hours. From the degreasing step, all degreasing methods can be roughly divided ……

2020-05-12

One. Introduction In the past two or three decades, metal injection molding (MIM) technology has produced increasingly complex parts, and its application fields have covered a wide variety of different industries. With the increasing demand for high-quality parts with small geometric distortions and strong material pro……

2020-05-09

The production of metal feed is an indispensable part of the metal injection molding industry, because the process technology requires that the injection raw materials must be uniform particles of a certain size, and powder cannot be used directly. Therefore, feed production is very important for the entire industry. A……

2020-05-09

Metal powder injection molding can be traced back to the powder injection molding of ceramic spark plugs that began in the 1920s. Powder injection molding over the next few decades has focused on ceramic injection molding. It was not until 1979 that the metal powder injection molding product formed by Wiech et al. won ……

2020-05-07

One. Commonly used metal powder injection molding materials Chinese and English comparison 1. Heavy alloy heavy metal sintered material with a density of not less than 16.5g/cm3. Such as: tungsten alloy containing nickel and copper. 2. A cermet cermet is a sintered material composed of at least one metal phase and at l……

2020-05-07

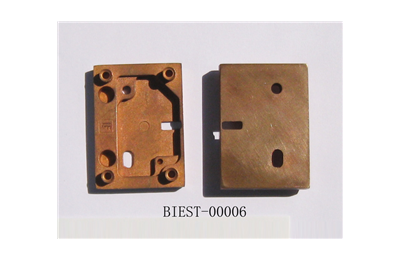

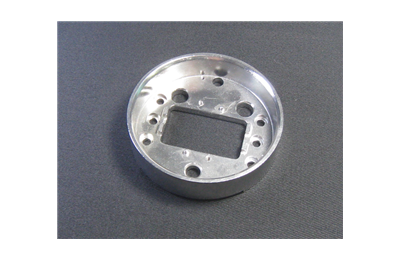

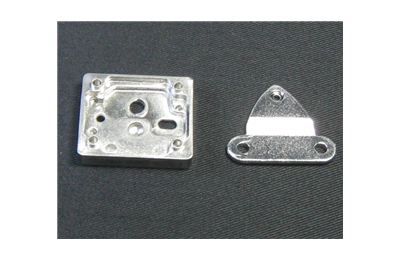

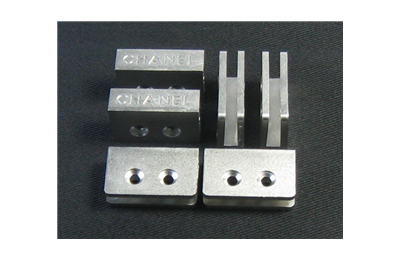

Today, MIM is widely used in various industries such as automotive, medical, electronics, industrial, and consumer. The products include auto parts, aerospace equipment, mobile phones, dental instruments, electronic radiators and sealed packaging, electronic connector hardware, industrial MIM products such as tools, fi……

2020-04-30

Metal powder metallurgy injection molding process is much better than powder compression molding and precision casting due to its dimensional complexity and mass production. So what are the core difficulties of metal powder injection molding? The following Best Editor will give you a brief explanation: First, the inter……

2020-04-30

Metal powder injection molding MIM technology is a new type of powder metallurgy near-net molding technology that metal powder injection molding manufacturers have extended from the plastic injection molding industry. MIM technology is to select metal powder and binder that meet the requirements of metal powder injecti……

2020-04-28

1. Brief introduction of MIM development: Metal Injection Molding (Metal Injection Molding, referred to as MIM) was invented in 1973 by Parmatech, California, w……

2020-04-28

Metal powder injection molding technology (Metal Injection Molding, abbreviated as MIM) is a field of rapid development in the field of powder metallurgy and industry in recent years. It is a new type of powder metallurgy formed by the combination of modern advanced plastic injection molding technology and traditional ……

2020-04-26

MIM machining parts are often used in our surroundings, and its arrival brings great convenience to our lives. The main reason for its popularity is corrosion resistance. Today Best will introduce the corrosion test of MIM processing to you. The corrosion test can be simple by immersion test. One of the corrosion tests……

2020-04-26

We always talk about the cost of MIM factory parts, but we don't know what it really means. A thing produced naturally has its use. Let's talk about the cost of MIM parts. There are costs in MIM factories throughout the industry, and the market and production methods vary greatly. However, the survey shows that most su……

Copyright: Shenzhen Best Precision Technology Co., Ltd.|Metal powder injection molding factory, manufacturer, customized company, supplier, process parts 粵ICP備18054342號